7 Tips for Improving the Cost Efficiency of Robotic Welding Operations

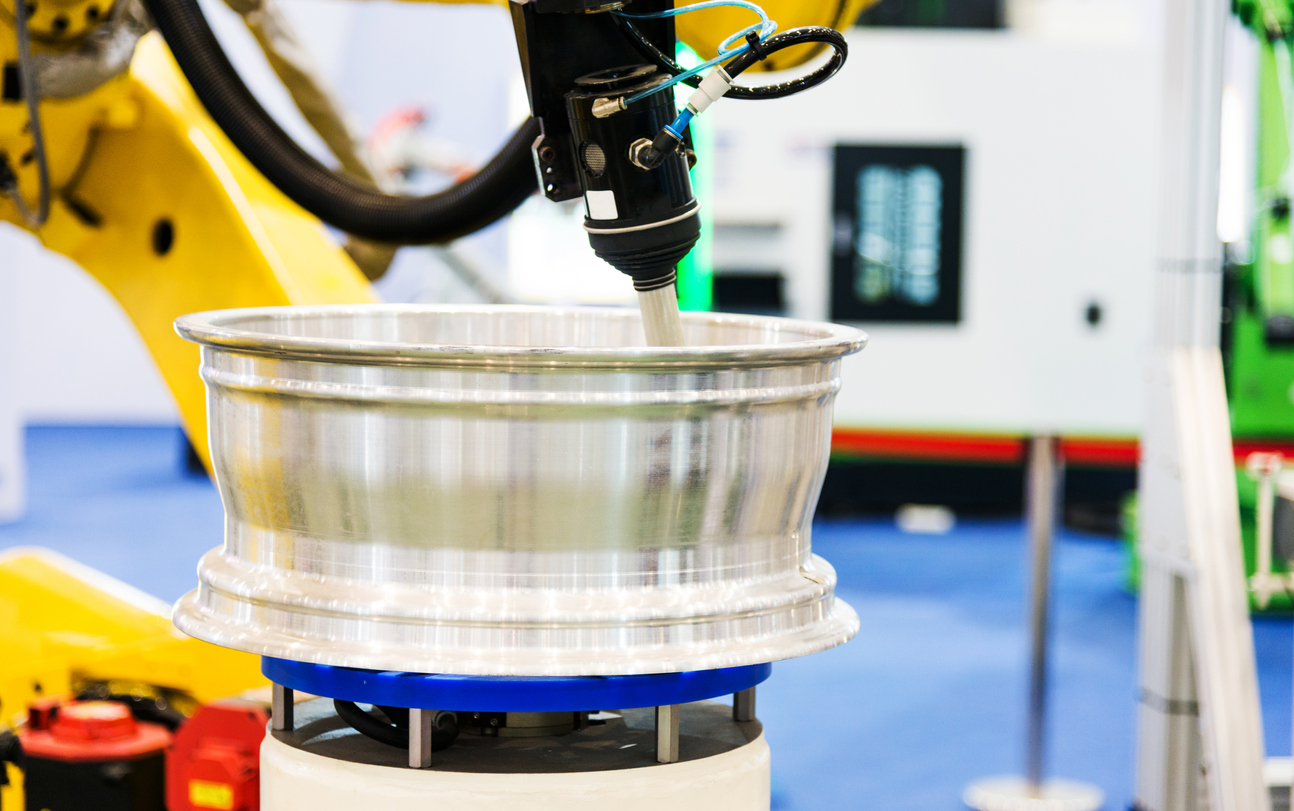

Robotic welding has revolutionized manufacturing by delivering higher productivity and precision compared to traditional manual methods. However, even after installation and programming, there are always opportunities to enhance performance and reduce costs. With the right strategies, robotic welding systems can be optimized for maximum efficiency and lower operational expenses.

Whether you're a seasoned manufacturer or just starting out with robotic welding, understanding how to cut costs without compromising quality is essential. Here are seven practical tips to help you improve the cost-effectiveness of your robotic welding operations.

How to Reduce Costs in Robotic Welding Processes

Robotic welding systems are advanced automation tools that require careful management to ensure optimal performance. By implementing smart practices and maintenance routines, you can significantly reduce the overall cost of these operations while improving productivity and equipment longevity.

Invest in robotic welding peripherals: Components like reamers, contact tips, wire cutters, and inspection tools play a vital role in maintaining consistent performance. Neglecting these accessories can lead to inefficiencies and increased downtime. Make sure you’re using high-quality peripherals that support smooth operation and long-term savings.

Optimize filler metal usage: Frequent changeovers of filler metal packages can slow down production. By selecting appropriately sized packages that last multiple shifts, you can reduce the number of interruptions and boost overall throughput.

Ensure reliable wire feeding: Poor wire feeding is a common cause of production halts and equipment damage. Regularly inspect and maintain feed mechanisms to avoid costly delays and extend the life of your welding system.

Extend contact tip lifespan: Contact tips wear out over time, but proper maintenance—such as cleaning and regular inspections—can greatly increase their service life. This reduces replacement frequency and lowers inventory costs.

Protect reamer blades: Damaged cutting blades in reamers can disrupt the process and add unnecessary expenses. Always ensure nozzles are properly aligned to prevent blade breakage and maintain consistent performance.

Utilize training programs: Many robot integrators offer comprehensive training for operators. Keeping your team well-informed about best practices not only improves safety but also enhances productivity and machine performance.

Implement preventive maintenance schedules: Routine maintenance helps identify potential issues before they become major problems. This proactive approach minimizes unplanned downtime and ensures your robotic welding systems run smoothly for longer periods.

While robotic welding brings many benefits, it's important to maintain and optimize your systems regularly. These seven strategies will help you achieve greater efficiency, reduce costs, and get the most out of your investment.

For more insights on maximizing the value of your robotic welding setup, explore Genesis Systems’ expert integration services and discover how we can help streamline your operations.

Building Materials And Equipment

Static Classification Machine,Static Classification Machines,Static Classification Equipment, Building Rotating Distribution Tray

Sichuan Shichuang Micro Nano Technology Co.,Ltd , https://www.scwnpowder.com